Inspection and prevention

PREVENTION

Checking and preventing a healthy turbo - WHY?

The turbocharger is an extremely healthy component, but for a number of reasons such as bad fuels, improper combustion, clogging of the exhaust system or leaks in the turbo system and improper operation, the operation of the turbocharger can be disrupted without the turbocharger itself being damaged. Almost all modern diesel cars have the so-called "Variable Geometry Turbo" system. What is variable geometry and how does it work, you can read in the "Turbochargers" section. In general, variable geometry (VNT) is very susceptible to blocking due to the accumulation of carbon, etc. Poorer fuels, improper operation of the car or too calm driving blocks this system and the turbocharger cannot work adequately, that is, reach and fulfill the required values from the engine computer. In this situation, the turbocharger is completely healthy, but does not function properly because of the blocked variable geometry. The only one hundred percent working solution in this case is the dismantling and installation of the turbocharger and cleaning the geometry or, in simple terms, the turbocharger maintenance. With timely and quality diagnostics and intervention and timely maintenance, the turbocharger will be saved and you will save unnecessary costs and extend its life. There are many proposals and options for cleaning turbochargers and performing maintenance, but unfortunately in many places not enough attention is paid and things are skipped or are done half-heartedly due to lack of equipment, turbo stands, professionalism, etc.

Whit US you will receive quality maintenance, which we will describe in the following stages of work:

1. Performing professional diagnostics of the car, which will establish and prove that the turbocharger needs maintenance.

- 2. If a problem related to the proper operation of the turbocharger is detected, after diagnosis, the turbocharger must be properly dismantled.

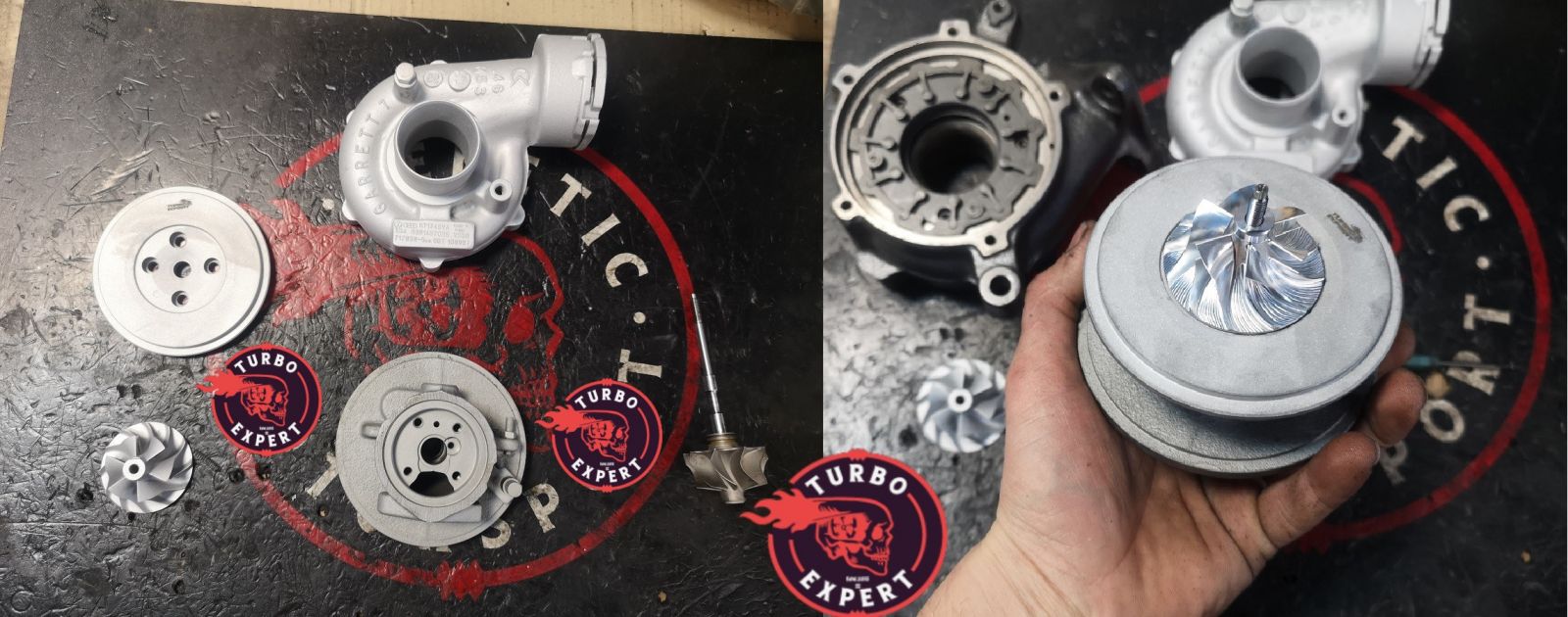

- 3. Next comes the actual disassembly of the turbocharger. The turbo is disassembled into its main components and the scrolls are separated from the middle part, the actuator and variable geometry are also dismantled, and everything is disassembled into its component parts.

- 4. Components such as the cold coil, the hot part (coil), geometry, etc. are washed and cleaned of oils, soot, etc. using ultrasound or hot water and pressure cleaning machines, which we have at our disposal, unlike many other service centers.

- 5. Now comes the fine cleaning in the Sandblasting booth and the Water Sandblaster which ONLY we have available. Yes, that's right, ONLY WE! (you can see and learn more in the section (Water Sandblaster).

.png)

- 6. Now we proceed to inspect all cleaned parts. If there are no damaged, worn parts or curvatures in the geometry or cracks in the housings, overheating or mechanical damage, everything is prepared for reassembly.

- 7. Before the final assembly of all components of the turbocharger, we test the middle part (core) of our VSR Turbostand. This test checks whether the turbocharger has oil leaks in a mode simulating a cold engine, i.e. not heated oil, and simulating a warm engine, i.e. heated oil between 70 and 100 degrees! Our Turbostand is the only one that offers a TEST of the turbocharger in 3 load modes and checking for oil leaks from the turbocharger, which are Simulating Idle, Medium and High RPM modes, in other words from 15,000 rpm. Through 80,000 - 100,000 rpm. to 135,000 - 170,000 rpm. For a certain time. If the tests are positive, we proceed to balance and complete the work on the middle part (core).

- 8. With successful previous tests and perfect results after the balance and oil leak checks, everything is reassembled in its original form to proceed to the final adjustments.

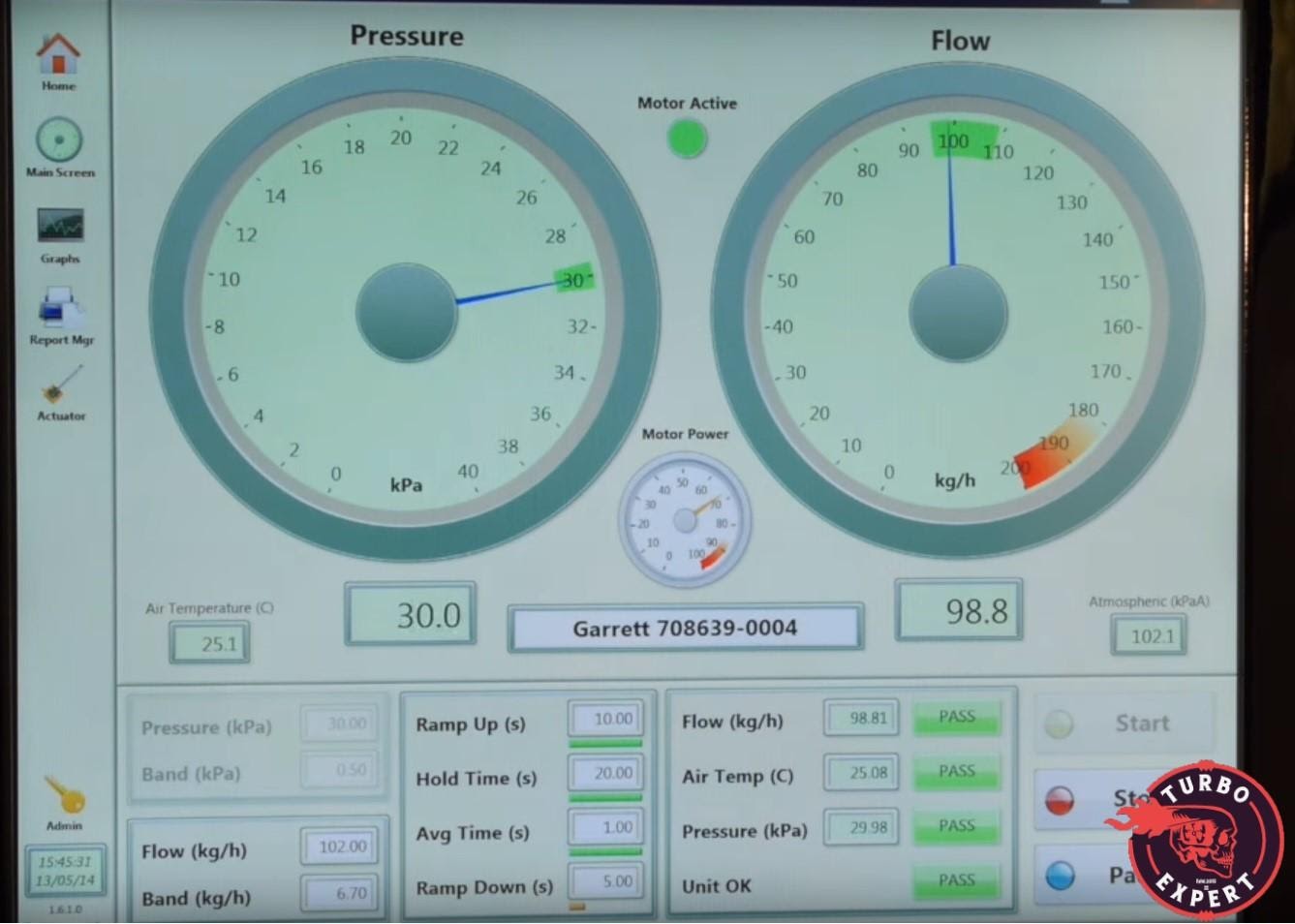

- 9. One of the last tests and checks is for the correct operation of the actuator (pneumatic or electronic, regardless of its type, we can test it) and checking all turbo parameters, using our Flow Bench stands, namely G3-min-Flow (Power) and Synthesis Flow Bench 2000S. In case of deviations from the factory parameters - YES, namely the factory parameters because our stands work according to factory data, we adjust the turbocharger until we achieve the perfect result.

- 10. The finished turbocharger is installed by our mechanics, following all the necessary steps for proper installation, so that the vehicle can return to perfect operating mode.

- 11. Finally, a full inspection through professional diagnostics on the road or on our dyno (depending on the conditions) is carried out to determine the smooth functioning of the turbocharger.

With us, the prevention, service and quality you will receive, as well as the professionalism and performance, are unrivaled!