Types of Turbochargers

VNT (variable geometry) & Waste Gate

As the engine speed increases, the amount of fuel burned per unit time also increases, thus increasing the speed, flow and volume of the amount of exhaust gases. The more exhaust gases pass through the turbine wheel (the hot blade / turbine part), the more they drive it (it spins at higher and higher speeds). In this way, the compression (cold blade) spins at higher speeds, compressing and forcing more air into the engine. In this process, all this loads the turbocharger, which can lead to its destruction, and here, to prevent this, the necessary mechanism intervenes to unload and prevent the turbocharger from overloading. This happens by opening and thus unloading the flow of gases and thus regulating its speed and pressure to safe set limits.

Turbochargers used in internal combustion engines differ primarily in the type of control of the unloading mechanism.

1. Variable geometry turbocharger - VNT

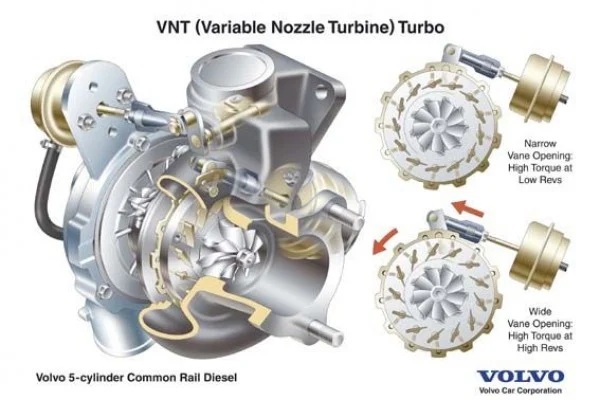

In this type of control of the turbocharger (with variable geometry), the pressure regulation is not controlled by a Westgate valve, but by a mechanism known as variable geometry VNT. Around the turbine blade (hot blade) are blades that move, and these blades change the speed of the exhaust gas flow that reaches the blade. When the blades are in the closed position, the speed of the gases driving the turbine blade increases, with the same volume of exhaust gases, while the blades direct the exhaust gases to the outer (peripheral) part of the blade, which exerts a greater torque on the axis (center of the blade) and in this way it rotates faster. When the blades are open, the gas flow is at a lower speed even at the same volume compared to closed blades. When gas is supplied and, accordingly, with an increase in speed, we get more gases and, accordingly, the blades open more and thus the same pressure is obtained on turbochargers at different engine loads and different amounts of exhaust gases. In variable geometry, the blades are driven by a lever, the end of which is again attached to a vacuum valve (or in other words - an actuator) or by an electric motor (electronic actuator). This type of variable geometry turbochargers, compared to those with a WASTEGATE mechanism, have a significantly smaller turbo hole or, in other words, turbo lag. This type of variable geometry control is used only in diesel engines, because the fine elements of this system cannot withstand high temperatures and therefore cannot withstand gasoline engines.

Here you can see the work of variable geometry in the turbocharger :

1. Turbocharger with Waste Gate .

This type of turbocharger equipped with this type of Waste Gate mechanism is also called a bypass valve, which when opened allows part of the exhaust gases to pass through a channel and in this way these gases bypass the hot fin and go straight to the generation. With this type of control, the amount, volume and speed of the exhaust gases that drive the turbocharger fin remains constant. Here, as the engine speed increases, the Westgate opens more and more and takes more and more exhaust gases straight to the generation surrounding the turbine fin (that is, gases do not pass through the hot fin and do not have any effect on the operation of the turbo).

Keep in mind that the Westgate and the vacuum valve are two different things!