Turbo Repair

Turbocharger Repair

WE at Turbo-Expert strive to offer the highest quality repair of all types of turbochargers. Only with us will you be able to receive comprehensive service, including everything related to your turbocharger!

What needs to be done and do we do it before proceeding with turbocharger repair?

- We perform a comprehensive diagnostics of the car, with which we aim to determine how the turbocharger works. This way, unnecessary turbo repair is avoided in cases where the problem is not related to it.

- Turbocharger Installation and Disassembly. We offer the complete procedure for dismantling and installing the turbocharger with us, thus you do not need to deal with other companies and bring the turbocharger to us for repair. We take care of everything, thus saving your valuable time and in this way we can carry out the necessary checks on the turbo system, exhaust system and oil system, which is extremely important and which almost no one does!

Turbocharger (TC) repair is a complex process involving several stages.

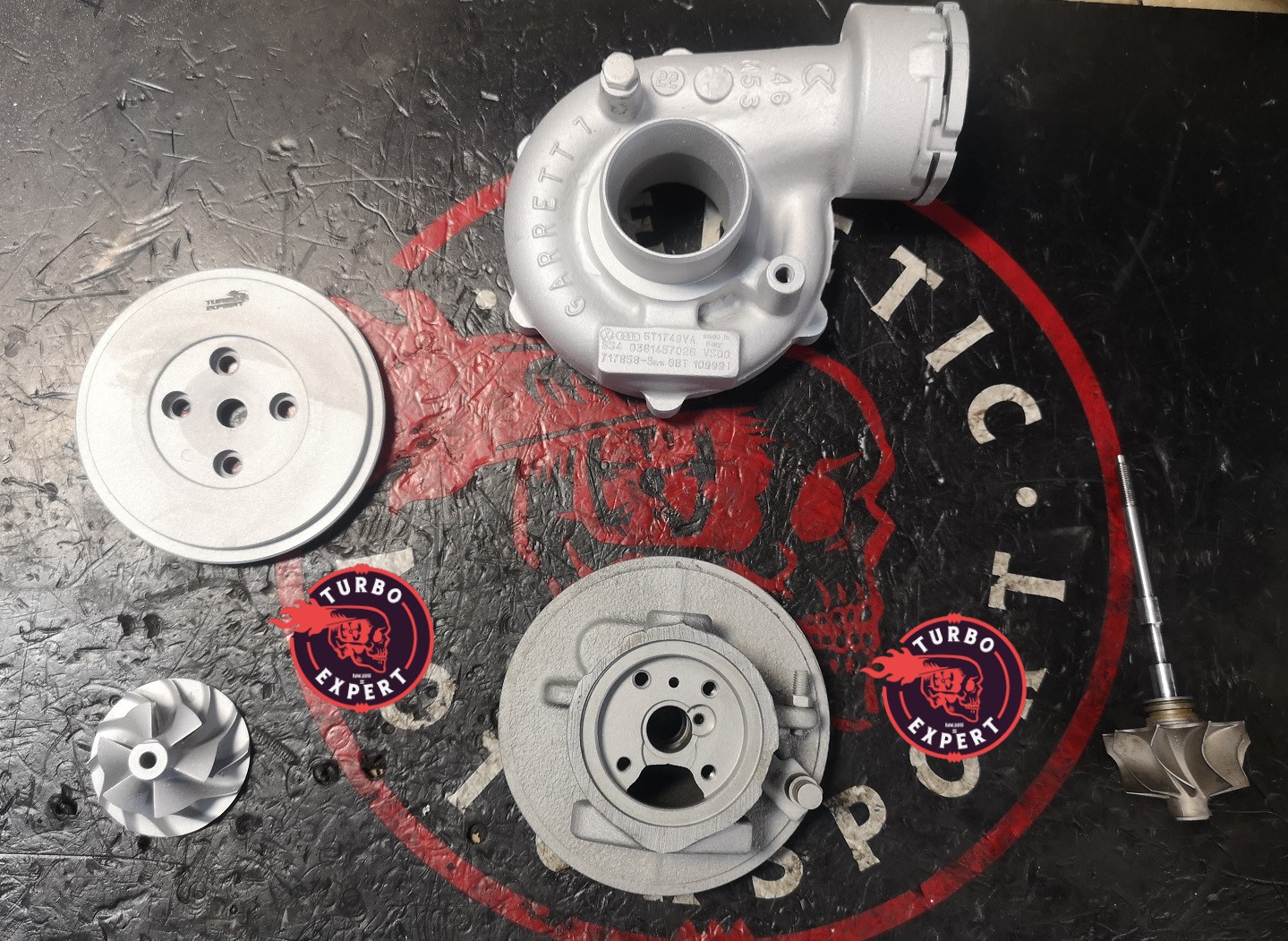

1 - DETERMINATION OF DEFECT AND DAMAGE – after opening the TC, each component is examined and analyzed in detail (bearing body, shaft, compression vane, housings – aluminum and cast iron). Depending on the wear of the various elements, it is determined whether the compressor is subject to repair and the possible causes of its failure. Therefore, each repair is individual and depends on which part is "fit" and the possibility of replacing other "unfit".

II. ESSENTIAL PART. TYPES OF REPAIRS.

1. Replacement of a repair kit (RK) (Repair Kit; Set) – this type of repair is subject to any turbocharger that is within the permissible wear, this means that the main parts have remained unaffected by mechanical damage. The repair kit itself contains (bushings, axial bearing, segments, flinger, seals).

*We use parts of our own production under the Turbo-Expert brand, and those from proven leaders in the industry such as, Kode, Mellet, TC, etc.

2. Partial repair – repair including item 1, as well as replacement of certain parts (axle, bearing body, compression vane, disc to the compression part, snails) that are worn beyond the permissible limits.

3. Replacement of the working cartridge (C.H.R.A.) – Replacing the working cartridge means almost a complete replacement of the compressor, since the CHRA is the main and only mechanical element in the compressor. This means that the only usable parts are the two scrolls (aluminum and cast iron).

CLEANING – after performing I, a quality cleaning of the old usable parts and their assembly into a complete turbine follows. The latter is preceded by a balance of the central working cartridge.

- BALANCE – Balancing is performed on a highly specialized VSR stand to ensure precise operation and long use of the turbocharger.

2.Airflow and VNT variable geometry tuning and electronic actuator setup/training - with FLOW Bench –G3!

3.Once everything is ready and the entire process has been followed and completed, all necessary documents from the tests are issued certifying that the turbocharger has passed them successfully and is ready for use:

Subsequent checks after recycling the turbocharger or installing a brand new one:

1. Careful installation of the recycled turbo

When installing the repaired or new turbocharger, it is mandatory to install new gaskets and inspect the oil lines and their correct connection, conductivity, etc. It is imperative to inspect and check the exhaust system in order to determine a clogged catalyst or particulate filter, and if there is a blockage, cleaning or other method is required to eliminate the problem. It is mandatory to check all air ducts or the entire turbo system and if there are traces of oil, etc. Flush and blow out all air ducts, as well as the intercooler, in order to remove residual parts (pieces or debris) obtained when the turbocharger broke. Such pieces can break the recycled or new turbocharger. All vacuum hoses and cracked air ducts are checked - cracked cooler, split hose, loose clamps, etc.

All this can be done with us in one place because we have all the necessary equipment!

2. Final diagnostics.

After proper installation of the turbocharger, it is necessary to perform diagnostics to confirm the correct operation of this turbocharger, the engine and its control mechanisms, as diagnostics are not performed on site like most service stations, but when the car is in motion and under load to show the real values.

Note: Problems related to the engine, exhaust system, turbo system and some control valves can lead to damage to the turbocharger. The correct operation of all these components is a necessary condition for the flawless operation of the repaired turbocharger. The final comprehensive diagnostics is an extremely important process, which unfortunately is often neglected. The necessary diagnostics can be performed by our specialists!

We suggest you take advantage of our package conditions to save unnecessary headaches, time and money, while maintaining a full warranty and driving comfort for your car.